News

Understanding Arc Flashes and Why Professional Studies Are Critical for Safety and Compliance

The heat level of an arc flash, however, is immense - nearly beyond comprehension. The National Fire Protection Association (NFPA) 70E requirements include rules related to arc flash studies. These potentially hazardous studies require the expertise of trained professionals.

Immense Heat

Let’s take a moment to define the terms.

An arc flash is a dangerous electrical explosion that occurs when an electrical current flows outside its intended path (i.e., the air) between two ungrounded conductors or between an ungrounded conductor and the ground. (phase to phase and phase to ground).

The NFPA adds, “Although air is normally nonconductive, air that has become ionized—meaning its particles have gained and lost electrons—creates a conductive, gas-like material known as plasma, through which electric current can flow. Electric arcs usually form as a result of a number of factors, such as high voltages or currents, moisture content, and damaged or degraded insulation.”

According to the NFPA, the arc flash explosion can reach temperatures over 35,000°F (19,400°C), which is hotter than the sun’s surface, a balmy 10,000°F (5,600°C). The extreme temperature alone creates an arc flash - and serious danger for anyone in proximity.

“Arc flash incidents can ignite clothing, cause structural fires, and produce particles of molten metal, causing severe or even fatal burn injuries,” OSHA explains. “At these high temperatures, most items within 3 feet (0.9 meters), including skin and flammable clothing, will burn, melt, or vaporize. Most arc flash burn injuries occur when the arc ignites flammable clothing and not from the arc itself.”

While there are protocols for protecting staff and facilities from Arc Flashes, injuries and deaths due to electrical explosions can and unfortunately, do occur. A study by the Fire Protection Research Foundation (FPRF) estimated there are up to 10 arc flashes daily in the US, or approximately 2700 annually. Others suggest the incident rate could be as high as 30,000, with over four hundred fatalities as a result.

A Necessary Evil

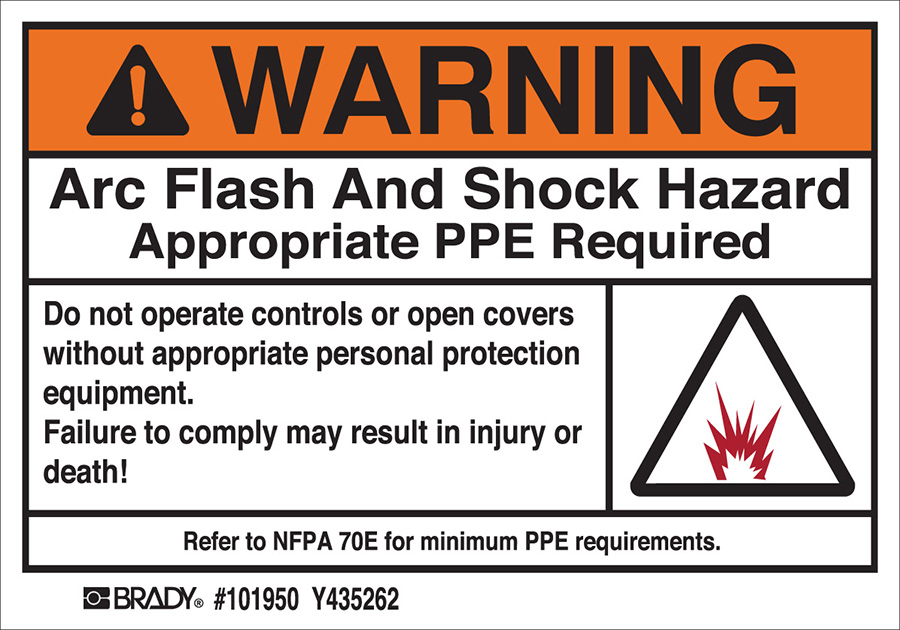

An electrical engineer conducts an arc flash study of a building’s electrical distribution system to determine the potential energy level of an arc explosion that could occur when a worker interacts with the system. When the study is completed, each piece of necessary electrical equipment is labeled based on its incident energy level.

Why engage with arc flash and conduct this potentially dangerous study?

First and foremost: safety. Upon completing an arc flash study, electricians can view the label and determine the appropriate PPE to enhance their safety when engaging with electrical systems in the event of an arc flash. If employees disregard the warnings provided by the study and label while working on the systems, they could be seriously injured (or worse).

Enhanced safety extends beyond the electricians and other staff who may engage with the electrical systems. Conducting an arc flash study also demonstrates to employees that employers are committed to the safety of the work environment. The study can also reveal faults with electrical systems. With the discovery, systems and facilities can be made safer.

Discoveries of faulty systems also have economic benefits. Systems can be improved, resulting in enhanced performance and increased reliability. Therefore, work can continue uninterrupted, and downtime is eliminated.

The Electricity Forum adds another reason: “Your electrical system is constantly evolving. Equipment upgrades, layout changes, or service additions can shift fault current values or protective device settings. If left unchecked, these changes increase the risk of catastrophic failures.”

Finally, an arc flash study is required to meet current regulations associated with NFPA 70E; failure to comply may result in citations and fines because this standard is enforceable by OSHA. Furthermore, many insurance companies are now requiring maintenance programs and/or updated arc flash studies as a condition of underwriting a policy or may increase premiums for those that do not comply.

The Electricity Forum elaborates on the regulation. NFPA 70E recommends reviewing arc flash studies:

- At least every five years

- Any time system modifications are made

- After fault current capacity changes

- When safety standards or PPE categories are updated

An arc flash study requires a preceding coordination study, though not all coordination studies include an arc flash study. This section of the arc flash study examines whether the protective devices (circuit breakers, fuses, etc.) in the electrical system are configured to operate in the correct sequence during a fault.

Protective devices isolate the fault. By limiting the fault, damage to the system is minimized to the area where the issue occurred, and it reduces the chance of arc flashes and other hazards. Therefore, a coordination study can mean the difference between a whole system going down (and needing repair and/or replacement) or one element.

“It [coordination] ensures faults are isolated to the smallest possible section while allowing the rest to function,” according to Electrical Contractor magazine. “Failure to implement selective coordination correctly can lead to catastrophic failures and compromised safety, operations and compliance.”

Help with your Arc Flash Study and Coordination

Our professional electricians and electrical engineers are experienced in completing arc flash and coordination studies. Have the team inspect your electrical systems to ensure they are running as designed and maintain a safe facility.

Click here to learn more about Miller Electric’s maintenance services.